Robotic Welding Market Outlook

The global robotic welding market is set to experience significant growth over the coming years, with a projected Compound Annual Growth Rate (CAGR) of 8.5% from 2025 to 2034. This growth is driven by the increasing adoption of automation in manufacturing processes across various industries. The rising demand for high-quality, efficient welding processes, coupled with the reduction in human error and labor costs, is fueling the demand for robotic welding systems. Additionally, the growing trend towards Industry 4.0 and smart manufacturing is expected to further propel market growth as companies seek to enhance productivity and operational efficiency.

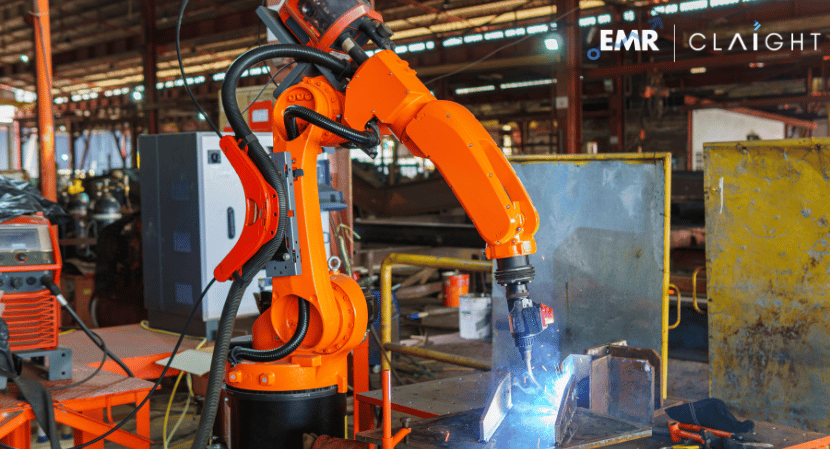

Robotic welding systems offer numerous advantages over traditional manual welding, including improved precision, speed, and consistency. These systems are widely utilized in industries such as automotive, aerospace, construction, and electronics, where the demand for high-quality welds is paramount. As companies continue to focus on reducing production time and enhancing the quality of their products, the demand for robotic welding systems is expected to witness robust growth.

Robotic Welding Market Share

The robotic welding market has seen substantial growth in both size and share, driven by the increasing adoption of automation and advancements in robotic technologies. The automotive industry, in particular, has been a major driver of market growth, as it relies heavily on robotic welding systems for assembling vehicle components. In addition to automotive, other industries such as aerospace, construction, and electronics are also contributing to the market's upward trajectory as they increasingly adopt automated welding processes to improve production efficiency and reduce operational costs.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/robotic-welding-market/requestsample

In the competitive landscape of the robotic welding market, leading players are continuously innovating to capitalize on emerging opportunities and meet the evolving demands of end-users. Companies are focusing on developing advanced robotic welding solutions that are equipped with artificial intelligence (AI) and machine learning (ML) technologies, enabling them to offer more precise and adaptive welding processes. Furthermore, strategic initiatives such as mergers and acquisitions, collaborations, and geographic expansion are being employed by key players to maintain their market position and gain a competitive edge.

As industries worldwide continue to embrace automation and smart manufacturing, the robotic welding market is expected to witness sustained growth. The increasing demand for high-quality welds, reduced production time, and lower operational costs are key factors driving the market's expansion across various regions and sectors.

Robotic Welding Market Segmentation

The robotic welding market is segmented based on type, payload, application, and industry. By type, the market is divided into arc welding, spot welding, laser welding, and others. Arc welding is expected to dominate the market, driven by its widespread use in automotive and manufacturing industries. Spot welding is also anticipated to witness significant growth due to its extensive application in the automotive sector for joining sheet metal components.

In terms of payload, the market is segmented into low, medium, and heavy payload robotic welding systems. Low-payload robots are primarily used in industries such as electronics and electrical equipment manufacturing, while medium- and heavy-payload robots are utilized in industries requiring high precision and strength, such as automotive and aerospace.

Robotic welding systems find applications across various sectors, including automotive, aerospace, construction, electronics, and metals. The automotive industry is the largest end-user of robotic welding systems, accounting for a significant share of the market. The construction industry is also emerging as a key segment, driven by the increasing use of robotic welding in infrastructure projects.

Geographically, the robotic welding market spans North America, Europe, the Asia Pacific, Latin America, and the Middle East and Africa. The Asia Pacific region is expected to dominate the market, owing to the rapid industrialization in countries such as China, Japan, and South Korea. The region's robust automotive and electronics manufacturing industries are key drivers of robotic welding demand.

Robotic Welding Market Growth Analysis

The robotic welding market is in a strong growth phase, driven by several key factors. The increasing need for automation in manufacturing processes, coupled with the rising demand for high-quality welds, is fueling market growth. Robotic welding systems offer improved accuracy, speed, and efficiency compared to manual welding, making them an attractive option for industries seeking to optimize their production processes.

One of the major growth drivers of the robotic welding market is the automotive industry, which accounts for a substantial share of the market. The automotive sector relies heavily on robotic welding for assembling vehicle components, including body panels, frames, and exhaust systems. As the demand for automobiles continues to rise globally, the need for robotic welding systems in automotive manufacturing is expected to increase.

Moreover, the aerospace industry is also contributing to the growth of the robotic welding market. The use of robotic welding systems in aerospace manufacturing helps achieve high precision and strength in the assembly of aircraft components, ensuring safety and durability.

In addition to these factors, the growing trend towards Industry 4.0 and the adoption of smart manufacturing technologies are expected to boost the demand for robotic welding systems. Industry 4.0 integrates advanced technologies such as AI, ML, and the Internet of Things (IoT) into manufacturing processes, enabling companies to achieve higher levels of automation and operational efficiency.

Robotic Welding Market Trends and Opportunities

Several key trends and opportunities are shaping the robotic welding market and driving its growth. One prominent trend is the increasing use of AI and ML technologies in robotic welding systems. These technologies enable robots to adapt to different welding conditions in real-time, improving the accuracy and efficiency of the welding process. As AI and ML continue to advance, their integration into robotic welding systems is expected to further enhance the capabilities of these systems, opening up new opportunities for market players.

Another key trend is the growing focus on sustainability and environmental concerns. As industries seek to reduce their carbon footprint and improve energy efficiency, robotic welding systems are being developed to consume less energy and produce fewer emissions. This focus on sustainability is expected to drive the demand for energy-efficient robotic welding systems in the coming years.

Additionally, the increasing adoption of collaborative robots, or cobots, in the welding industry presents a significant opportunity for market growth. Cobots are designed to work alongside human workers, enhancing productivity and safety in welding operations. The growing demand for cobots in industries such as automotive, electronics, and construction is expected to create new growth opportunities for market players.

Furthermore, advancements in sensor technology are improving the accuracy and reliability of robotic welding systems. Sensors enable robots to detect and adjust to variations in the welding process, ensuring consistent weld quality. The integration of advanced sensors into robotic welding systems is expected to drive the market's growth by improving the performance and versatility of these systems.

Competitive Landscape

The global robotic welding market is characterized by intense competition, with several key players striving to maintain their market position and capitalize on emerging opportunities. Leading companies in the market include:

- ABB Ltd.

- FANUC Corporation

- Yaskawa Electric Corporation

- KUKA AG

- Kawasaki Heavy Industries Ltd.

- Panasonic Corporation

- Lincoln Electric Holdings, Inc.

- DAIHEN Corporation

- Universal Robots A/S

- Hyundai Robotics

These companies are focusing on product innovation, research and development, and strategic collaborations to stay competitive in the market. For example, ABB Ltd. has introduced advanced robotic welding solutions equipped with AI and ML technologies to enhance welding precision and adaptability. Similarly, FANUC Corporation has developed robotic welding systems that offer high-speed and high-precision welding capabilities, catering to the needs of industries such as automotive and electronics.

Read More Reports:

https://www.expertmarketresearch.com/articles/top-epc-companies

https://www.expertmarketresearch.com/reports/frac-sand-market

https://www.expertmarketresearch.com/reports/us-financial-services-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Eren smith, Corporate Sales Specialist – U.S.A.

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com

Aus. Site: https://www.expertmarketresearch.com.au