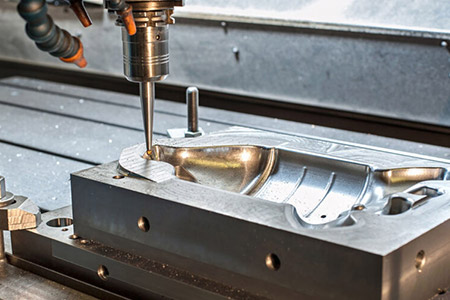

When it comes to the production of machined parts, the accuracy of the machining process is frequently one of the most important factors in determining the overall quality of the machined components. This is because the overall quality of the machined parts is directly correlated to the accuracy of the machining process. This is due to the fact that the precision with which the machining process is carried out has a direct bearing on the overall quality of the machined parts. This is because the precision with which the machining process is carried out has a direct bearing on the overall quality of the machined parts. This is one of the reasons why this is the case. Machining precision components on a computer numerically controlled (CNC) machine is in and of itself an exceptionally challenging machining method. On the other hand, it is able to produce results that are superior to those that are produced by conventional machining methods. Those results can be found in the following:advantages that are absent in a significant number of the various other types of processing methods that are currently available to choose from. Because of the higher level of handiwork that is associated with the first choice, we strongly advise going with a good tube rather than a good one in the majority of situations.

This is because of the higher level of craftsmanship that is associated with the first option. This is due to the fact that the first choice is a more expensive alternative. How do we go about selecting an appropriate provider, and what characteristics of potential service providers should we center our attention on when making this choice? When it comes to the companies that supply components that are manufactured in accordance with drawings, the answer to this question is of the utmost significance. Machining and other forms of working with sheet metal are examples of this type of processing. When there are two options available, our standard recommendation is to select a good tube rather than a good one when there is a choice that needs to be made between the two.

Your first order of business should be to devise a model that can be applied to the task of determining which vendors provide the most desirable features and benefits, and then use that model to rank the vendors in order of desirability. The formula that is presented here as an illustration is just one example of the many different kinds of formulas that could be utilized:The level of performance that can be reasonably anticipated from a provider is equal to the product of that provider's level of capability multiplied by their level of willingness to deliver that level of performance. We have compiled a list of points on the basis of the information and experience gained by all of the purchasing managers of milling parts online, and the following points can be found on that list:

1. Make sure that the total amount of interest is factored into your calculations.

When looking at the requirements for the processing of CNC parts, you will notice that the parts that have low precision requirements and a large number of parts are primarily looking for suppliers who have good coordination, low prices, and a large production capacity. This is because these parts require a lot of individual pieces to be processed. This is because the processing of these parts requires a significant number of separate components. This is due to the fact that the processing of these parts requires a substantial number of individual components to be used. This is due to the fact that the processing of these parts requires the completion of a significant number of individual components.

2. Consider the word will

The willingness of various suppliers to work together is the single most important factor to take into account when it comes to the machining of small batches of a number of different varieties. Another essential aspect that needs to be taken into account is the degree to which the development direction of the supplier's boss aligns with the direction that the industry is moving in. This is an important factor that needs to be taken into account. This is the consideration that needs to be given the most weight in order to arrive at the conclusion that this particular action is the best one to take. Products that are offered in a wide variety but have a low production volume are not a good fit for high-volume suppliers because they do not allow for enough flexibility in order fulfillment. This is not only because there is a low production volume, but also because there are a large number of different varieties. Both of these factors contribute to this phenomenon. In addition to this, in order to ensure that they are the ideal match for one another, it is dependent on the positioning of the suppliers, or the customers that they aim to serve, respectively.

This is done in order to guarantee that they are the perfect match for one another. This is done in order to ensure that they are the ideal complements for one another, which is why it is done. This is done to make sure that they are the perfect complements to one another and is the reason why cnc milling online is done. On the basis of this, we hope to be in a position to be in a position to be able to provide the entire industry chain service in the field of robotics for a variety of businesses, universities, and scientific research institutions located all over the world. Specifically, we hope to be in a position to be able to provide this service to businesses located in the United States. In particular, we are speaking about the scientific discipline of robotics.

3. the ability to comprehend how one's own eyes interpret the world around them

There are a very large number of distinct categories of capabilities, some of which include the capability of design, the capability of proofing, the capability of mass production, the capability of assembly, and the capability of testing. Moreover, there is also the capability of assembling. Your requirements for suppliers ought to serve as the compass that guides your choice of supplier, and you ought to go with one that possesses capabilities that are in line with those requirements. In other words, your choice of supplier ought to be guided by your requirements. To put it another way, the criteria you have set for the suppliers you work with should direct your choice of supplier. To put it another way, the standards that you have established for the vendors that you collaborate with should serve as the basis for your choice of vendor.

4. Keep an Eye on Delivery

You will be able to determine whether the production capacity is based on the current order situation, the number of customers, or something completely different by analyzing the data regarding the percentage of on-time deliveries made to their other clients. This will allow you to determine whether the production capacity is based on the current order situation, the number of customers, or something completely different. With this information, you will be able to determine whether the production capacity is based on the current order situation, the number of customers, or something completely different. As a result of this, it will be possible to investigate their value stream, as well as the output rate and utilization rate of key equipment, the adaptability of production capacity, and a number of other topics connected to this field. The idea of saturation describes the precarious situation where it is impossible to predict whether or not there will be spare capacity available to guarantee that your order will be delivered on time. This idea also goes by the name of "available capacity," which refers to the question of whether or not there is capacity beyond what is required. After an order has been placed, the ease with which the order can be managed and tracked is another factor that will play a role in determining how quickly the order will be fulfilled.

This is going to be the case regardless of whether the provider manages production by making use of a production management system or by delegating the task of managing production to a specific individual.