For CNC lathes equipped with live-tool capability, the situation became even more difficult to comprehend and understand how to deal with. Previously exclusive to the milling department, operations on the lathe were now carried out by the other departments, which was a significant improvement. As a result of this development, determining which machine is the most appropriate for producing a particular part has become significantly more difficult to determine.

Candidates for the Lathe Operator position should have the following qualifications:

-

In some cases, turning some parts on a lathe is a no-brainer because of their complexity

-

Consider the differences between a spool valve piston and a hydraulic hose fitting, for example, and how they differ from one another

-

Because of the cylindrical symmetry of these components, as well as their complex external geometry and difficult internal features, they are required to be permanent fixtures in the turning department

This valve body will never be spun on a lathe due to the large milled surfaces, detailed pockets, and intersecting bores on it that interface with the turned parts. This is true regardless of how capable the lathe is with live tools.

A few of the reasons for our CNC machining service's shift away from milling and toward turning parts are listed below. Through the incorporation of live-tool (end mill) equipped CNC turning centers into our already extensive three-axis milling service, we can improve the surface finish on cylindrical features while simultaneously lowering the overall cost of production for customers. A further advantage of using the lathe in the production of parts that are on the verge of becoming too large for our milling capabilities is that it is more productive. Turned components, on the other hand, are excellent candidates for small-scale production if the goal is to eventually produce in small quantities.

What is your recommendation for the best camera lens housing for the foreseeable future, and would you be willing to share it with the rest of the world? To give you an example, how about creating a ground-breaking drive shaft for a lawnmower that includes milled flats and cross-holes that can be threaded into the shaft itself? Most likely, we will have the capability of providing you with a turned prototype for that particular geometry.

With regard to cost and time savings, turning parts has a number of advantages over milling parts in this situation. It has been previously reported that mill operators who experience upset stomachs as a result of large length to diameter ratios on pistons and shafts may have to stop working for a period of time. On the other hand, turning a set of candlestick holders for your Aunt Martha's 60th birthday party is a piece of cake when done with a lathe.

Illustrations from the Ordinary World

Considering a few common household items that can be used as models if you're still not sure which parts are appropriate for lathe use may help. Because of the smooth, regular shape of the pint glass in question, as well as the fact that its length is several times greater than its outside diameter, turning a pint glass on a lathe is a simple process. When using a machining center, this is not the case, on the other hand. Turning a coffee cup with one hand, on the other hand, is nearly impossible due to the protruding handle and finger-ready hole on the rim.

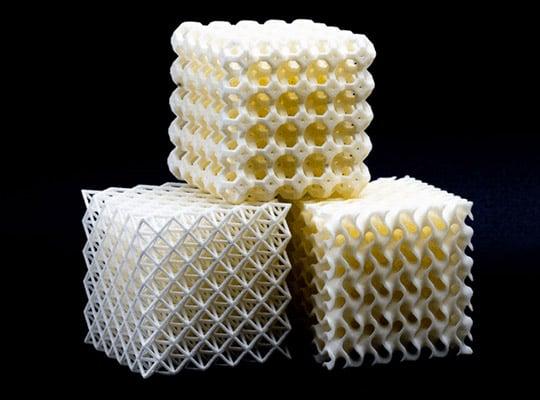

With the assistance of a lathe, those three-pound dumbbells that have been collecting dust in the back of the closet for a long time could be turned. custom 3D printing is possible to rotate the wide, relatively deep recessed area where your hand grips the bar with a simple grooving routine because of the amount of force required to turn it; this is a feature that would be impossible to cut on a milling machine because of the amount of force required to turn it.

Small teacup saucers or similar items could serve as a guide in either direction. Using concentric ridges and curved surfaces, this can be accomplished by milling or turning; all that is required is a precise G-code and a suitable cutter to complete the task. Even if the saucer is turned, it is almost certain that the alternative method of turning the saucer will be both faster and more efficient in terms of material consumption than turning the saucer by hand.

Another feature that would be beneficial is the inclusion of a sprinkler-connected hose barb. The v-shaped grooves would require the use of a special cutter if done on a machining center; however, on a lathe, the grooves can be cut with a standard turning tool without any modifications. Even though milling those small mag-wheel-like cutouts on the face of a replacement wheel for a barbecue grill would be difficult, if not impossible, on most turning machines, the same holds true for a replacement wheel for a barbecue grill

According to the manufacturer, soup cans and salt shakers, water bottles, and flower pots are just a few of the shapes that lathes are capable of producing. Some people are perplexed as to what the difference is between milk cartons and picture frames. This is not the case in any way. Aluminum and brass, as well as low carbon and stainless steels, as well as steel alloys and titanium, are just a few of the materials that junying can use to create his masterpieces.